If you are looking for the correct way to select, place and route your current measuring shunt resistor on a PCB then stick around as I will be sharing a bunch of tips & tricks that I learned while designing and building my own boards over the past years.

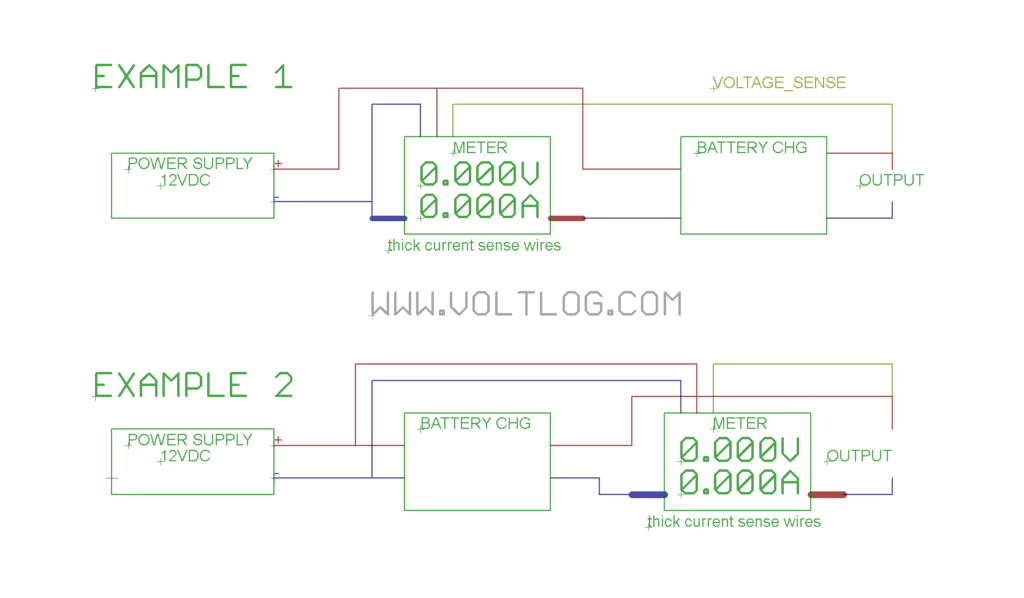

A shunt resistor can be used in multiple ways but for the purpose of this video we are interested in using it for measuring current, this means it needs to be inserted in series with the device under test. It can either be inserted in a high side configuration as shown in this example but it can also be inserted in a low side configuration. These two typologies have their advantages and disadvantages.

Here is a side by side comparison, when used in a low side configuration there is a ground offset which depending on your application may or may not pose problems. When used in a high side configuration, you must use a differential input amplifier for sensing the voltage drop while in a low side configuration you can get away with single ended.

Another thing that might be important, in a high side configuration you have the ability to detect a short on the load, while on the low side configuration you can’t do that. Also in a low side sensing configuration, you are not able to sense and account for additional leakage currents through stray secondary paths from the load to ground. This list might not be complete, there might be other differences to consider, these are just the ones that I had to consider in my designs.

But let’s say you’ve figured out the topology you want to use and you are now faced with choosing your current shunt resistor. Can you just pick your typical metal film 1ohm resistor from your favorite distributor? You can, but you won’t get the best results. Probably the most important factor you want to consider when choosing your shunt resistor is the temperature coefficient or the temp co as engineers like to refer to it. This will tell you how much your resistor value is going to change with variations in temperature.

Every system you build will probably see a variation in temperature at board level and so if you calibrate your system to calculate the current for a given resistor value and that resistor value changes with temperature, you are going to introduce significant errors in your measurement.