I’ve talked about EasyEDA in the past in Voltog #58 where I reviewed their free online pcb design software. Now the guys from EasyEDA asked me if I wanted to review their pcb service and I said yes. They offered to fabricate my pcb’s for free and also included a steel stencil.

The design for these pcb’s is my dark load project, the electronic dummy load that I’ve started working on over a year ago but never got around to finishing the project. The main reason for not finishing the project was because I don’t like writing code that much so after spending some time on the STM32, writing code for testing the on-board hardware, initializing the OLED display and the ADC I got bored and kinda stopped working on the project.

However there were some hardware improvements that I planned to do on that design, especially with the fan pwm control circuit. I wanted to switch to an inverted buck dc-dc converter topology driven from the microcontroller with PWM. This way I would get a nice varying dc voltage that would reliably vary the speed to any type of dc fan connected, but that’s another story.

Just so it happens, I recently reviewed the pcb assembly service from 7pcb.com so I have a spare blank pcb from their service so we can use this pcb which is an identical design for comparison. The only difference is that EasyEDA does not offer a matte black soldermask finish so I had to go with normal glossy black on their service.

How is the ordering process on EasyEDA?

The ordering process is an important part that might help you decide whether or not you will order from a specific shop. If you go to EasyEDA PCB ordering page, you will be greeted with a simple layout, you just need to drag&drop your gerber files and select the various options for the pcb panel.

They let you select the quantity, pcb thickness, soldermask color, surface finish, copper weight, temp rating, holes/traces/spacing, pretty much standard options with every board house these days.

You can also check an option to get a steel stencil if you need it and in the end you will get a build time estimate, a price estimate and you can also simulate the shipping cost. In my opinion this is a pretty straightforward, easy to use ordering form.

I ordered two pcb designs: first was 100x60mm ($75 for 5pcs with steel stencil) second was 106x55mm ($57 for 5pcs), black soldermask, ENIG finish. The total cost was $132 plus shipping. Shipping to Romania via DHL was another $37.

How is the silkscreen quality?

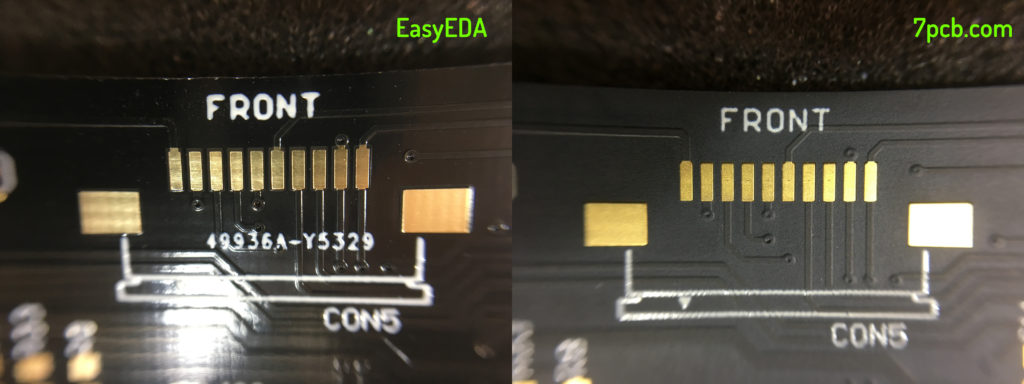

Unfortunately I no longer have my microscope so I am only using a macro lens to take close-up pictures of the pcbs but we can still observe the silkscreen quality and resolution in the picture below.

The vertical copper pads are 0.6×1.9mm in size and the text block saying “FRONT” is about 5.7×1.2mm. The printing on the 7pcb.com panel looks to be a bit sharper, not by much, just a bit. We can also notice EasyEDA placed some text under that connector on the top side of my pcb. Personally I don’t like it when they place text on my pcbs, but at least in this case they placed it under a connector where it would never get seen after the assembly.

Soldermask expansion and alignment

The soldermask alignment is not perfect but certainly acceptable and comparable between the two. It’s shifted on the same axis on both panels, but it doesn’t obstruct the copper pad in any way so that is perfectly acceptable, especially considering those passives are 0603 so the actual size is quite small.

The panel from 7pcb.com seems to have tighter tolerance for mask expansion and alignment but as I mentioned, the one from EasyEDA will work just as well as there is no pad obstruction happening.

No soldermask between the microcontroller pads for the EasyEDA panel while we have the mask on the 7pcb.com panel. I am not sure if 7pcb.com have a better more precise process for the soldermask application or is it just something specific to the matte black soldermask, maybe a different process specific to the matte black? Overall the soldermask print was uniform and without any scratches or problems on both panels.

Holes offset

This is where a microscope would of been handy because just with a macro lens is not really possible to get a feel for the holes offset.

These are 0.7mm drill holes in the fan connector and they look very well aligned on both panels. Maybe just a very small offset on the 7pcb.com panel but that is perfectly acceptable and won’t cause any trouble.

Overall very good drill hole alignment with no or very minimal offset on these two panels.

What about the steel stencil?

As mentioned in the start of this article I also got a steel stencil with this order to make the assembly work easier. There isn’t much you can review or say about a steel stencil. It was shipped nicely sandwiched between two pieces of plywood so it wouldn’t get damaged during shipping. It’s your standard frameless laser cut stencil that you can get from most pcb fab houses.

The specs for this laser cut steel stencil are: no frame, 0.12mm thick, no fiducials, no eletropolishing (electropolishing removes the micro burrs associated with laser cuts, leaving behind smooth aperture walls for easy transition of paste from the stencil to the pads), 280×380 size for a cost of $17.9 and 0.7Kg added to the shipping weight. On their website you can select multiple options but I went with the standard ones.

Conclusion

Although I don’t have any cost information on the 7pcb.com panel, I think the price should be similar so it was a fair comparison. In terms of the ordering process EasyEDA have clearly invested in their online platform so the ordering process is very smooth and fast.

The quality of these pcb’s is very similar but the one from 7pcb.com stands out in a few areas like silkscreen quality and soldermask expansion and alignment.

Should you order pcbs from EasyEDA? I’m tempted to say the pcb’s from EasyEDA would directly compete with the ones offered at a lower price by shops like SeeedStudio Fusion, Elecrow, DirtyPCBs, and others. A fair comparison would be to order the same pcb from one of these lower cost shops and check if they are the same quality. If they are the same quality then, I wouldn’t recommend buying something more expensive unless you benefit from something else like the ordering experience.

For example if you are using EasyEDA online cad tool, then it would simply be a matter of a few clicks to get your design into production. In that case it might be worth to pay extra because it will save you time.

I think hobbyists who usually don’t need any extra bells and whistles will continue to order from the cheapest service available because they just need one-off pcb designs for their small projects and they don’t care how fast the order is processed or how the ordering process goes, they just want the cheapest option possible.

Nice review. as an Embedded HW Engineer, not liking to write a code is like shooting yourself in the foot. I’m having similar struggle.

It depends, at least in my case it’s not a general feeling but sometimes, like in the case of this project, I quickly got bored.

About the pricing, when I do small boards from easyeda it is usually the same exact price to do 10 or 200 panelized. You have to play with the quote system a bit.

The price of PCB manufacturers in China is almost the same, there will be no difference, but if you PCB prototype, you will find that in addition to the price, the service is also very important, because it involves tariffs, logistics, communication, and ability, you need to be assured. The manufacturer came to help you solve the problem. Yes, easyeda, I knew that the price was a little cheaper on the surface, but I chose PCBWAY after the comparison. I don’t mean anything when I say it. I suggest you try it.