Inside the box of the BST-863 we have the station, a really nice and heavy stand for the tool piece, a total of 3 nozzles, a grounding strap and a power cord. The first thing I notice is the hose which pretty thick, certainly thicker than what I had on my old Gordak station but seems to be softer material. The way it’s designed with the tool standing vertically in the stand makes the air hose forms this loop which depending on your bench setup might or might not bother you but it’s something to consider. But I like the quality of the stand, it’s heavy and feels very sturdy, you get this accessory here which allows you to remove the nozzles while hot and the station has a sensor to detect when the handle is in the stand.

Adjustment of temperature and air level is made through this touch screen control. I’m a bit anti touch screen control on test gear so I would’ve preferred some switches on the front panel but don’t get me wrong, the touch screen works well on this unit, it has nice big touch keys and after setting up your presets you are likely not going to need to adjust the temperature you will just be using the presets like leaded, lead free and another one for heatshrink maybe.

Is this cheaper station a good alternative to the Quick 861DW? This video review should provide you with enough info to decide which one to buy.

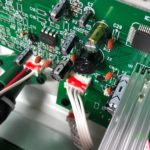

Here are some high resolution images from the teardown: