Welcome to a new voltlog, it’s time for another upgrade on my Creality CR10 3D printer, and this time it’s about the print surface. By default this printer comes with a glass print surface which sits on top of the aluminium bed and that has worked fine for most prints and settings I’ve tried but occasionally I would get some adhesion problems and with glass you need to wait until the part has cooled down in order to remove it. Not such a big deal but there is this newer magnetic print surface, which has two parts, you get the bottom part with adhesive that you stick to the aluminium build plate of the printer and you get the top part which sticks magnetically to the other part.

This way, with the top surface I should get better adhesion and when the print is finished I can just remove the print surface from the printer to have it cool down faster or maybe for easier removal because I could just bend the surface to cause the part to unstick.

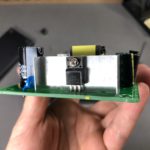

I’m also going to upgrade the bottom heater of the bed by installing one of these insulation sheets, this should help it reach working temperature faster and maybe it will use less power to keep it at working temperature.